Bravo Trittico Executive

Absolute creative freedom for the art of gelato, pastry products, chocolate and savory foods

Gelato, sorbet, slush ice (Granita), pastry cream, Semifreddos, meringue for macaroons, Italian meringue, Swiss meringue, fruit jelly, buttercream, Mousseline cream, Pâte à Bombe, Chocolate Pâte à Bombe, Bavaroise, lemon curd, Bechamel, Sauces, and Jams

A combined machine that’s less than 10 square feet that with a double inverter for the highest levels of pastry making, chocolate, artisan gelato, and all types of international cuisine.

Gelato, pastry products, chocolate, and savory food

Talk with our friendly experts.

Tom Graves Founder, Owner

CALL (949) 212-9753

Get a QuoteWith over 40 years of innovation, the Trittico® Executive is the first and only complete laboratory enclosed in just one machine.

Trittico Executive is the first multi-function machine for gelato, chocolate, pastry, and catering. Thanks to its micro-processor, the machine automatically handles the cooking, cooling, and the emulsion of your recipes. Even the least experienced personnel can perform all operations without mistakes or waste. Trittico Executive also allows you to temper white, dark, and milk chocolate: the machines respects the temperatures to the tenth grade using the appropriate temperature sensors and the special patented cooling device to ensure the required accuracy during the whole process! Trittico Executive is equipped with an electronic brain that automatically manages 17 different programs in the hot side and 17 different programs in the cold side. You can also customize many other bakery products, gelato, and refreshments, with great variety and flexibility. Trittico adapts to the professional with ease. Thanks to the software that controls the speed variator, with Trittico Executive you will be able to make fruits and chocolate sauces, toppings, granitas and semifreddos’s as well as pastry cream, to add more variety to your show-case. We start from nature and create added value for gelato makers. And it couldn’t be any easier with Trittico Executive, an all in one gelato machine

Trittico Executive is the first multi-function machine for gelato, chocolate, pastry, and catering. Thanks to its micro-processor, the machine automatically handles the cooking, cooling, and the emulsion of your recipes. Even the least experienced personnel can perform all operations without mistakes or waste. Trittico Executive also allows you to temper white, dark, and milk chocolate: the machines respects the temperatures to the tenth grade using the appropriate temperature sensors and the special patented cooling device to ensure the required accuracy during the whole process! Trittico Executive is equipped with an electronic brain that automatically manages 17 different programs in the hot side and 17 different programs in the cold side. You can also customize many other bakery products, gelato, and refreshments, with great variety and flexibility. Trittico adapts to the professional with ease. Thanks to the software that controls the speed variator, with Trittico Executive you will be able to make fruits and chocolate sauces, toppings, granitas and semifreddos’s as well as pastry cream, to add more variety to your show-case. We start from nature and create added value for gelato makers. And it couldn’t be any easier with Trittico Executive, an all in one gelato machine

Unique two-tank pasteurization and freezing structure.

Unique two-tank pasteurization and freezing structure.

Made of one upper vertical tank (1), where the pasteurization begins, and one lower horizontal tank (2), where the pasteurization phase is completed and the mixture is then freezed. The two independent tanks can work simultaneously with the advantage for the artisan to carry on two different processes at the same time. In fact, while the mixture is freezing, it is possible to start a new production cycle, that means the pasteurization of a new product. Because the two tanks are connected through a patented internal conduit ,avoiding any external environment contamination, it guarantees the best hygiene of the products and their absolute quality.

Bravo’s patented Ionic System will tell you automatically when your gelato is perfectly CREAMY, DRY with VERY FINE ICE CRYSTALS, delivering an healthy, balanced, soft and creamy gelato, stable in the shop window

Bravo’s patented Ionic System will tell you automatically when your gelato is perfectly CREAMY, DRY with VERY FINE ICE CRYSTALS, delivering an healthy, balanced, soft and creamy gelato, stable in the shop window

This Ionic System determines when the gelato is ready for extraction by understanding when your gelato is dry and contains exactly the right amount of air. This preserve the creaminess and softness that is typical of traditional Italian gelato. The machine automatically beeps when the gelato is ready to be extracted and it’s at its ideal level of dryness, delivering a perfect gelato texture every single day while maintaining your creativity .

Technical Features |

|

|

|

Advantages and Strengths |

|

|

|

|

Works with Equilibrio Smart Scale

|

“Bravo’s Trittico machine creates not only a superior product; it also has multiple functions for great versatility, and saves tremendous time and money. Bravo’s equipment is the answer to tomorrow’s technological needs for our industry.”

CHEFS JACQUY PFEIFFER & SEBASTIEN CANONNE, M.O.F. The French Pastry School of Chicago

“I find the Trittico Executive indispensable, not only for its speed and precision control, but also for the range of pastry applications possible, well beyond ice cream and gelato.”

MICHAEL LAISKONIS, Creative Director of New York City’s Institute of Culinary Education

“Bravo Trittico is a very versatile and easy to use equipment. We use this machine for a lot of different preparations in our School and all the visiting Chefs are very enthusiastic about it.”

JEAN-MARIE AUBOINE CHOCOLATIER, Master Chocolatier, Owner and President of JMA Chocolates

|

|

| Standup Floor Models Bravo 305, 457, 610, 1020 305 & 457 Available in air or water-cooled 610 & 1020 Water-Cooled |

Counter-top Models Bravo 183 Available in air or water-cooled |

|

|

|

|

|

| Three bladed mixer with metal scrapers | Special whisk for Table Top models pâte à bombe, butter cream, meringue, etc. available for models 305, 457, 610, 1020 | Multi-language display | Extraction chute from upper tank. Jams, fruit jellies, chocolate, etc… |

Probe in direct contact with the mix |

Specifications |

Model |

||||||||

|---|---|---|---|---|---|---|---|---|---|

| 183 [Table-Top] | 305 | 457 | 610 | 1020 | |||||

| Prod. for cycle | Gal | 0.79 | 1.32 | 1.84 | 2.64 | 5.28 | |||

| Average hourly production *1 | Gal | 3.17/4,75 | 5.28/7.92 | 7.92/11.88 | 11.88/15.85 | 21.13/31.7 | |||

| Voltage | Volt/Hz/Ph | 230/60/3 | |||||||

| Refrigeration condenser | Water | Air | Water | Air + Water | Water | Air + Water | Water | Water | |

| Power | hp | 7.1 | 7.2 | 7.8 | 7.9 | 8.4 | 8.7 | 12 | 23.2 |

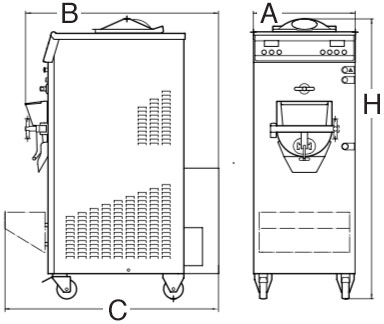

| Width (A) |  In inches In inches |

19.7 | 19.7 | 20.1 | 8.4 | 20.1 | 20.1 | 24 | 24 |

| Depth (B) | 32 | 32 | 31.5 | 38.2 | 37.4 | 37.4 | 37.4 | 45.3 | |

| Depth (C) | 34.4 | 40.7 | 40.4 | 40.4 | 40.4 | 48.2 | |||

| Height (H) | 33.1 | 33.1 | 55.1 | 55.1 | 55.1 | 55.1 | 55.5 | 55.7 | |

| Weight *2 | Lbs | 269 | — | 564 | — | 681 | — | 763 | 1124 |

*1 Hourly production may change according to type of mixture and finished product density. *2 Water or Air: cooled system self contained. Air+Water: cooled system self contained. *3 The weight of the air cooled machines will be estimated before the shipment

Bravo Trittico – Start of the revolution: in 1974 Genesio, founder of Bravo, submitted the first of a long series of patents: Trittico, the first and only complete laboratory enclosed in just one machine, which is less than three square feet can pasteurize and batch freeze high-quality artisan gelato. A patent that radically changes the way of thinking of the artisan gelato workshop. With Trittico a new way of making gelato has begun: the Trittico method, the new Bravo adventure, one machine that’s the most copied machine in the world today.

Bravo Brochures and Specification Sheets

Bravo Trittico Mechanic

Bravo Trittico Business

Bravo Trittico Executive

Bravo Gelmatic M

Bravo Pastmatic

Bravo Trittico EVO

Bravo G-20

Refrigeration & Other

Related Products

Bravo Trittico M 18 Table-top

Heat & Freeze Machines for making Gelato, Ice Creams & Sorbets

Read More

Equilibrio Fill Good – Professional Filling Machine

Heat & Freeze Machines for making Gelato, Ice Creams & Sorbets

Read More